A New Frontier in Nylon Dyeing

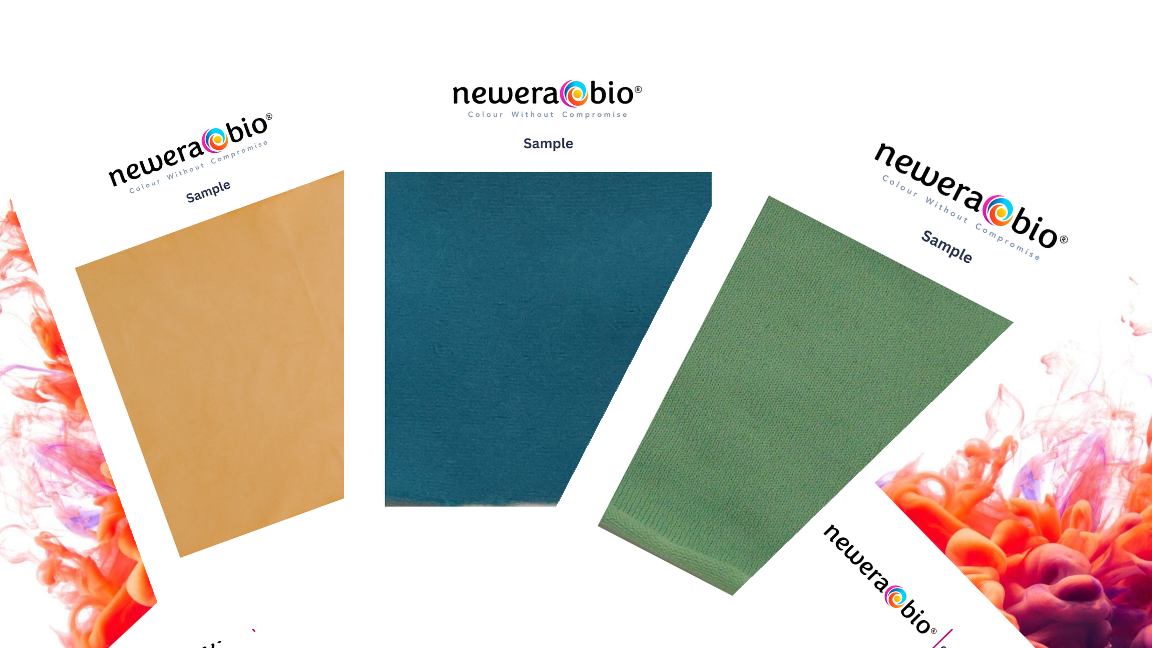

Newera Bio: Nylon Samples Dyed with Microbial Dyes & Bio-Based Binders

Our series has explored the dyeing of silk and wool - two natural fibers prized for luxury and performance. Today, we turn to nylon, the synthetic workhorse of activewear and technical gear.

Though they come from a worm, a sheep, or a lab, silk, wool, and nylon share a hidden similarity: they all have the same kind of chemical “hooks” for colour to latch onto. This is because they are all amide-based fibres, built around nitrogen-rich sites that attract and bind dye.

This shared trait is why the same class of dyes works on all three and why the environmental downsides of conventional dyeing, like toxic wastewater, high energy use, and fibre damage, affect them all.

Our approach has always been guided by a simple principle: true sustainability works with a fibre’s chemistry, not against it. Having created clean solutions for natural protein fibers, we’re now applying the same thinking to synthetic polyamides like nylon where change is just as urgent.

Nylon: The Engineered Performance Fibre Evolves

Since its commercial debut in the 1930s, nylon has revolutionized textiles[1]. From its iconic beginnings in hosiery to its essential role in activewear, swimwear, and technical gear, its strength, elasticity, and resilience are unmatched. It is the second most used synthetic fibre and made up 5% of global fibre market in 2024, with 7 million tonnes[2] produced globally.

Traditionally a petrochemical-derived thermoplastic, nylon’s environmental narrative is being rewritten. The industry is pivoting decisively toward a cleaner lifecycle. It is anticipated that by 2050, recycling, CO2-based and Bio-based Nylon will become the mainstream.

Bio-Based Nylons: Pioneering materials like PA 6,10 and PA 11[3] are now derived from renewable castor beans. These offer identical performance with a significantly reduced carbon footprint, as the plants sequester CO₂ during growth.

Next-Gen Bio-Polymers: Breakthroughs in fermentation are producing nylon intermediates from plant sugars, yielding fully bio-based polymers such as PA 5,10[4].

Circular Nylon: Waste like discarded fishing nets and industrial plastic is being regenerated into high-quality recycled nylon (e.g., ECONYL®), tackling pollution and conserving resources[5].

Infinite Enzymatic Recycling: moving beyond mechanical or basic chemical recycling toward precise biological processes. This approach leverages engineered enzymes to break down materials to their core molecular building blocks, which can then be reassembled into new, high-quality material without degradation. Samsara Eco is the leading player in this filed.

This is critical progress, but it addresses only half of the equation. These innovations redefine the fibre's origin, yet the conventional dyeing process which is synthetic chemical-intensive, energy-heavy, and polluting remains a glaring contradiction. A garment made from castor-bean nylon but dyed with toxic chemistry represents an unfinished revolution. True sustainability requires clean chemistry from molecule to finished, coloured fabric.

Dyeing Nylon: it’s all about the “Hooks”

Nylon is built like a long chain with special “hooks” occurring intermittently throughout the polymer (called amino groups). To dye it, these hooks become positively charged in acidic dyeing conditions so they can attract and hold negatively charged dye molecules.

But nylon has far fewer hooks than fibres like wool and silk, so getting deep, even colour is challenging. The fibre is also dense, so it needs high heat for the dye to penetrate properly.

Because of this, only certain dyes work well:

Acid dyes are the best match for the hooks and are the most commonly used dye type for nylon.

Reactive dyes bond strongly via covalent bonds in acidic conditions but typically only used for dark shades.

Traditional nylon dyeing is notoriously resource-heavy and uneven, often requiring hazardous bisphenol-based fixatives for high colour fastness. In response to tightening regulations, bisphenol-free solutions like ours are emerging.

The Key Stages of Nylon Dyeing:

Surface Approach: Dye molecules move with liquid to fibre surface.

Adsorption: Dyes concentrate and bind to the positive ionic "hooks" on the fibre surface.

Diffusion: Heat (98 - 115°C for 30 - 60 minutes) opens the polymer structure, allowing dyes to diffuse deep inside.

Fixation: In the acidic bath, strong ionic bonds form, permanently fixing the colour.

To achieve consistent results, it is critical to manage the following variables during dyeing:

Control the flow: A leveling agent slows down the dye attachment for even colour.

Set the stage: The dye bath must be kept at the correct acidity (pH ~4.0-6.0) to activate nylon for consistent dye uptake and level results. Proper temperature, time, and controlled cooling allow the dye to diffuse fully into the fibre.

Lock it in: Fixing agents are often used to prevent the colour from washing out.

The Critical Issues with Current Nylon Dyeing

The conventional approach delivers vibrant, durable colours but with notable environmental and operational drawbacks.

Chemical-Intensive Effluent The discharge contains residual acid dyes, which are often resistant to biodegradation. Leveling agents and after-treatment chemicals add to the pollutant load. While less commonly associated with toxic metals than wool chrome dyeing, the synthetic chemistry persists in ecosystems.

Energy and Water Consumption High-temperature dyeing is energy-intensive. The need for multiple rinses and after-treatments escalates water usage, it consumes approximately 125 - 150 litres per kilogram of fabric[6].

Fibre Damage and Barre Prolonged exposure to high heat and acidic conditions can degrade nylon, reducing tensile strength. Achieving level dyeing remains a technical challenge, leading to Barré streaks and product inconsistency.

Limited Sustainability Profile For a fibre already moving towards bio-based and circular models, a chemically intensive dyeing process undermines its sustainability credentials and circular economy potential.

Alternative Approaches

The industry has sought improvements, but trade-offs remain.

Low-Temperature Dyeing (85 - 90°C) reduces energy use and fibre damage but may compromise colour fastness and depth.

Metal-Free After-Treatments replace syntans with eco-friendly options but can be less effective.

Digital Printing eliminates aqueous effluent for patterning but is not a solution for piece-dyeing solid shades

The fundamental limitation persists: most innovations address only one part of the problem, the energy, chemicals, or feedstock, but not the dyeing system comprehensively.

Our Innovation: A Comprehensive Solution for Next-Gen Nylon

We’ve developed an integrated system designed for nylon’s unique chemistry and aligned with its sustainable future. It centres on a proprietary, bio-derived auxiliary, bioBIND™, engineered to work with a new generation of high-performance, sustainably sourced colorants.

How It Works

We adapt our proprietary bioBIND™ technology, a biodegradable binder made from renewable resources for nylon. Its smart design creates tailored docking sites for dyes, ensuring a strong, precise bond through molecular recognition with nylon's chemistry. The result is superior colour without the need for synthetic auxiliaries or extreme heat This approach prevents fibre damage and uneven dyeing (“ barre” ), ensuring the nylon retains its essential performance properties: strength, stretch, and durability.

Newera Bio: Colour Depth Comparison

The Advanced Colorant Benefits

We pair bioBIND™ with a curated palette of bio-based colorants selected for minimal environmental impact – the next generation microbial dyes cultivated from bacteria, fungi and microalgae. By using bioBIND™ we avoid the use of bisphenol fixing agents like BPA whilst achieving industry level wash and rub fastness requirements. These acid dyes are with superior eco-toxicological profiles. The result is a system that meets conventional performance.

The process is ZDHC MRSL compliant, with readily biodegradable auxiliaries and significantly reduced chemical oxygen demand (COD) in wastewater.

Completing Nylon's Sustainable Transformation

Today’s market demands that performance and planet friendly are inseparable. Consumers seek the durability of nylon in activewear and outerwear but are increasingly scrutinizing its full lifecycle and impacts on biodiversity, climate and human health.

Brands at the forefront with bio-based and recycled nylon have redefined material sourcing. To complete the revolution, they must now address the harmful chemicals used in the dyeing process. The final product's integrity depends on it. The narrative of a garment made from upcycled ocean plastic is fundamentally broken if its colour is applied with harmful chemistry.

Our system bridges this final gap. It is the essential colour partner for next-generation nylons. By applying clean bioBIND™ chemistry to fibres designed for lower impact, we help brands achieve a holistic sustainability story where responsible sourcing meets responsible coloration, without compromising an ounce of performance.

It provides the reliable, vibrant, colourfast and level dyeing that mills demand, integrates seamlessly into existing infrastructure, and future-proofs supply chains against tightening sustainability regulations.

Colour the Future of Nylon Together

Let's collaborate to close the sustainability loop. We partner with brands, mills, and innovators to make high-performance colour clean, from molecule to material.

Newera Bio: Nylon Shade Card

See the Proof: Evaluate our technology with a Performance Swatch Kit (bio-based/recycled nylon samples and lab reports included).

Build Your Solution: Co-develop a tailored bioBIND™ application for your unique nylon fabric or functional need.

Please contact us via DM or visit our website www.newera.bio to discuss how we can redefine colour for the new era of nylon, together.

[1] https://www.performancedays.com/loop/focus-topic/2021-12-the-sustainable-future-of-nylon.html

[2] https://2d73cea0.delivery.rocketcdn.me/app/uploads/2025/09/Materials-Market-Report-2025.pdf

[3] https://circuvate.com/news/press-release-circular-sportswear-from-beans-project-receives-eu-funding/#:~:text=While%20traditional%20polyamides%20use%20oil%20as%20the,use%20of%20pesticides%20and%20with%20little%20water.

[4] https://www.nature.com/articles/s41598-025-23295-2

[6] https://textilelearner.net/water-consumption-in-textile-processing-industry/#:~:text=Substrate%20………………,the%20bleaching%20section%20is%20highest.