A New Era in Wool Dyeing

Newera Bio: Wool Samples Dyed with Microbial Dyes & Bio-Based Binders

In our previous post, we explored how silk's protein structure makes it an ideal candidate for eco-friendly dyeing. Today, we're turning to wool: another remarkable protein fibre whose natural chemistry creates extraordinary opportunities for sustainable colour innovation.

Wool: Nature's High-Performance

Australia dominates the global market for ultrafine Merino wool, producing over 80%[1] of the world's supply. This supremacy reflects decades of selective breeding and ideal pastoral conditions. The finest Merino wool measures under 22 microns in diameter, far thinner than a single human hair (50-100 microns), and in exceptional cases, even softer than cashmere. The productivity difference is striking; while a cashmere goat produces only 200-300 grams of usable fibre per year, a single Merino sheep yields around 4.5 kilograms of fleece annually, a staggering 15 times more material.

Wool has warmed humanity for over 10,000 years, from Bronze Age shepherds to modern fashion houses. Yet the very qualities that make wool exceptional, its warmth, durability, and natural beauty, have historically come with an environmental cost during dyeing.

The Architecture of Wool: Structure Meets Chemistry

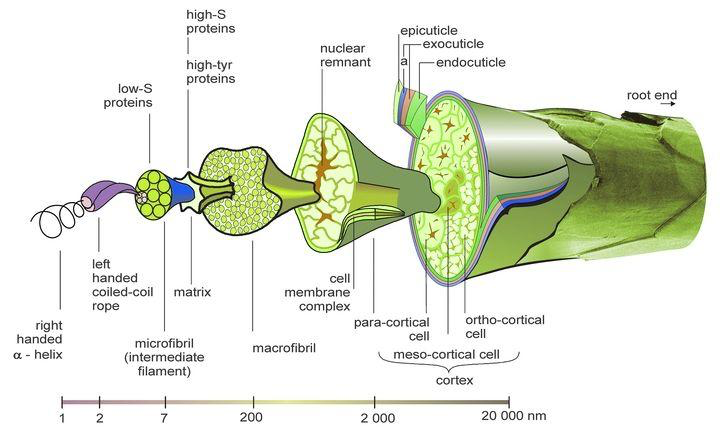

Understanding wool dyeing begins with understanding the fibre itself. Built from keratin, the same protein that forms human hair. Wool consists of multiple distinct layers. The outer surface features overlapping microscopic scales creating wool's characteristic texture. Beneath this lies the cortex, composed of protein-rich cells surrounded by a cell membrane complex which is crucial for dye transport[2].

Image Credit: Textile Study Centre

Unlike smooth cotton or uniform synthetics, wool's scaled surface and crimped structure create extensive surface area and porosity. Dye molecules enter at scale junctions and travel through the cell membrane complex, penetrating deep into the fibre's core.

Approximately 80% [3]of wool's weight comprises keratin proteins rich in amino acids, the key to its exceptional dyeing properties. At wool's isoelectric point (The pH at which a molecule has no net electrical charge) of pH 4.5-5.0[4], the fibre contains both positively charged ammonium groups and negatively charged carboxylate groups in balance.

This dual-charge system creates remarkable versatility: wool can accept acid dyes (negatively charged) that bond with positive sites, or basic dyes (positively charged) that bond with negative sites. The fibre's chemistry adapts based on pH. More acidic conditions create more positive sites, while alkaline conditions generate more negative sites.

Additionally, wool contains disulphide bonds, strong cross-links between protein chains that are critical for structure but also play a significant role in what happens during dyeing.

How Structure Dictates Dyeing Approach

Wool's architecture determines which dyes work and which processes succeed.

The amino acid composition makes wool particularly receptive to acid dyes, which form strong ionic bonds with protein chains across a pH range from highly acidic (pH 2-3) to near-neutral (pH 6-7). Metal-complex dyes, where chromium is incorporated into the dye molecule, offer outstanding fastness; however use of highly toxic metals like chromium should be phased out to protect workers and the environment. In some instances, reactive dyes may be used if not requiring highly alkaline dyeing conditions and form covalent bonds with the fibre, providing brilliant shades with excellent wash-fastness.

The Five-Stage Process of Wool Dyeing

Approach: Dye molecules are circulated evenly to the fibre surface by the movement of the dye liquor

Adsorption: Dye molecules attach to the fibre's surface, concentrating at the charged junctions between the scales

Penetration: Dyes enter the fibre cortex primarily by diffusing between cuticle cells (rather than through keratin plates) and fibre swelling is aided by high temperatures.

Migration: Dyes spread evenly inside the fibre by travelling along the microfibrillar pathways in the cortex. Level dyeing is achieved once the concentration of dyes is uniform throughout the cortex

Fixation: Dyes form stable bonds (ionic, hydrogen, Van der Waalsor through complexation) to lock the colour in place

The scaled, porous structure facilitates rapid adsorption and diffusion, but achieving strong fixation has traditionally required harsh chemistry.

Today’s Mainstream Approach of Wool Dyeing

Wool dyeing typically occurs at or near boiling (98-100°C) for 30-60 minutes. The fibre is immersed in a dye bath set to the appropriate pH with acid and auxiliaries. As temperature rises, dye molecules exhaust onto the fibre, travelling through scale junctions into the cortex. If reactive dyes are used, Glauber's salt controls uptake rate while levelling agents ensure even colour distribution.

For many dye classes, particularly chrome dyes offering superior fastness, mordanting with metal salts is essential. Most commonly potassium dichromate forms a bridge between dye and fibre, dramatically improving wash and light fastness.

Chrome dyeing, largely replaced with pre-metallised chrome dyes, remains commercially significant because it delivers exceptional light fastness critical for upholstery, outstanding wash fastness even in heavy shades, and consistent results. But at 200 litres of water per kilogram of fabric[5], the industry consumes roughly 200 billion litres annually for dyeing alone, discharged as contaminated wastewater after single use.

The Critical Issues with Current Wool Dyeing

The conventional approach delivers performance but at significant compromises.

Toxic Effluent

When metal mordants are used, each dyeing cycle generates wastewater laden with toxic metals (chromium, tin) that bioaccumulate in ecosystems and harm communities and biodiversity. Synthetic acid dyes are resistant to biodegradation and breakdown into toxic by-products (in the case of premetalised chrome dyes). Furthermore synthetic auxiliaries like leveling and dispersing agents used during wool dyeing can persist in the environment and damage wildlife. Despite treatment, residual metals and dyes often escape into rivers and groundwater.

Exploring Alternative Approaches

The industry has pursued several pathways, each with trade-offs.

Low-Temperature Dyeing (85-90°C) reduces fibre damage and energy use but requires specific auxiliaries and still relies on conventional dye chemistry

Metal-Free Wool Specific Reactive Dyes eliminate toxic metal discharge and offer brilliant colours but often show lower light fastness and can cause uneven dyeing on weathered wool

Natural and Early Microbial Dyes provide biodegradable alternatives but suffer from limited colour range, poor light fastness, and often still require metal mordants

Anti-Setting Systems preserve fibre properties but can cause yellowing and interact negatively with some dyes

The fundamental limitation: they address individual problems, toxicity or fibre damage or performance, but none deliver complete solutions.

Our Innovation: The Holistic Solution

We've developed an integrated system that eliminates the compromises above. It is a proprietary bio-based binder, bioBIND™ that works synergistically with advanced microbial pigments.

How It Works

Our binder is derived from renewable resources, is biodegradable and creates optimized, high-affinity binding sites specifically engineered for bio-based dye molecules. Unlike metal mordants creating toxic chemical bridges, our auxiliary works through molecular recognition, matching microbial pigments to specific sites on wool's protein structure.

This dramatically increases dye uptake and colour strength while simultaneously preventing disulphide bond rearrangement that causes permanent setting. The fibre retains its natural crimp, bulk, and mechanical properties.

Colour Depth Comparison

The Microbial Advantage - Performance That Aligns with Expectations

We pair our bio-based binder with next-generation microbial pigments cultivated from bacteria, fungi, and microalgae ultimately using agricultural waste as feedstock, achieving industry approved colour fastness across the colour spectrum.

Wool dyed with our system meets conventional benchmarks across all critical metrics: colour depth matching chrome dyes, wash-fastness grade 4-5 even in heavy shades, light fastness grade 3-4 for initial prioritized colours, and preserved fibre bulk, strength, and handle.

The entire system is ZDHC MRSL compliant, with no hazardous chemistry at any stage. Wastewater is non-toxic and readily treatable.

Conscious Threads: The Wool Standard for Modern Fashion

Today's wool market is experiencing remarkable transformation. Consumers increasingly prioritize both performance and provenance, seeking materials that deliver luxury without compromise.

Brands are leveraging wool's natural temperature control, moisture management, and biodegradability across expanding categories: performance activewear where merino outperforms synthetics, urban commuter wear combining natural wrinkle resistance with contemporary aesthetics, circular fashion initiatives where biodegradable wool fits regenerative design, and luxury knitwear where fibre quality defines brand positioning.

But this renaissance faces a credibility challenge. Consumers researching supply chains understand that “natural fibre” doesn't automatically mean “clean processing.” Wool dyed with toxic metals creates cognitive dissonance that undermines brand narratives.

Simultaneously, designers demand expansive colour palettes, batch-to-batch consistency, speed, and superior quality. Mills need straightforward, easy-to-implement solutions. Our system meets these needs directly, its clean chemistry fulfills sustainability goals, while advanced microbial pigments provide the vibrant, reliable colour and fibre integrity that drive sales, all with seamless integration into existing manufacturing.

Let’s Work Together to Lead Wool's Transformation?

We believe that the future of wool dyeing isn’t about choosing between performance and sustainability. It is about a system that can deliver both, colour without compromise.

We invite visionary brands, mills, and designers to pioneer this transformation.

Newera Bio: Wool Shade Card

Pilot Test: Request a Microbial Wool Swatch Kit featuring colours with lab reports and initial ISO testing results

Co-Development: Work together to invent signature colours using our microbial dye and bioBIND™ system tailored to your specifications

Please contact us via DM or visit our website www.newera.bio to discuss potential collaboration opportunities.